Why Trex®?

Trex Outperforms Wood

Our high-performance composite deck boards are engineered to resist fading, scratches and stains, and eliminate time-consuming maintenance so you’ll never step foot in the stain aisle again.

Frequently Asked Questions

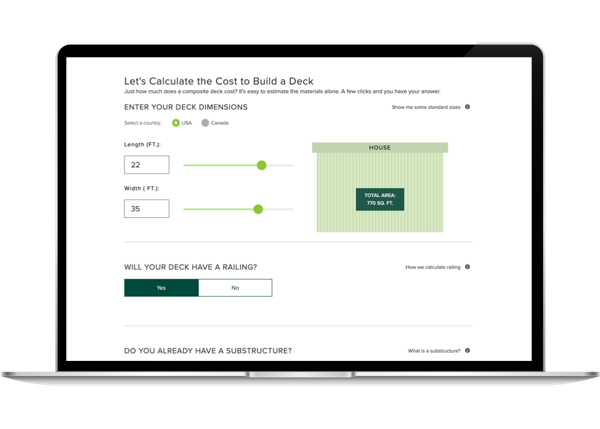

On average, the estimated material cost for a composite deck runs from $15 - $30 per square foot (including substructure, decking, hardware and fasteners).* We recommend using our online cost calculator tool and guide to get an estimate for your project's cost. For a true cost estimate, reach out to a Trex retailer or TrexPro deck builder.

*Average price range excludes Trex Signature® decking, our luxury decking collection. Trex actual material costs and install costs can and will vary based on geographic area, site location, seasonality, design complexity, whether the product is stocked locally, and additional features such as stairs, angles, curves, lighting, etc. For most professionally installed projects, materials constitute up to one third of the total cost

Unsure if your deck is made with Trex? Start by reviewing our decking product lines to compare your decking against our collection. If you still can't tell, then please contact us over the phone at 1-800-BUY-TREX.

Trex decking is designed for a low-maintenance experience. A simple soap-and-water clean is all it takes. For more details, refer to our Care and Cleaning section.

Try Our Additional Planning Tools

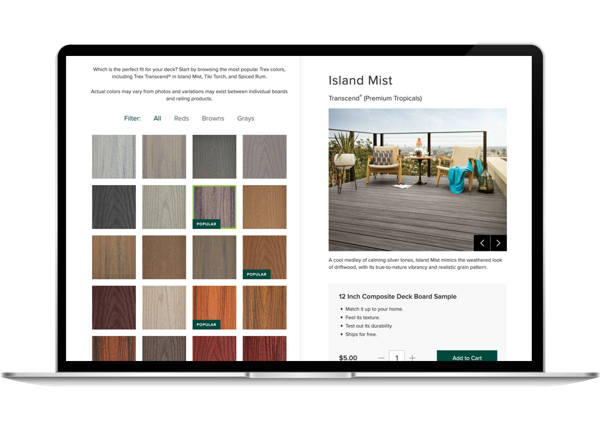

Trex Offers Something For Everyone

Bringing your outdoor ideas to life has never been easier.

This content was partially or fully generated by AI and has been reviewed by our team to ensure accuracy and relevance.